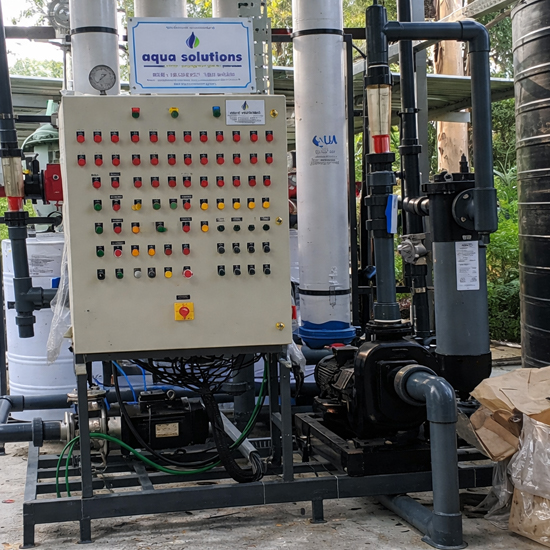

AQUA SOLUTIONS has been a leading water and wastewater treatment manufacturer for 17 years.

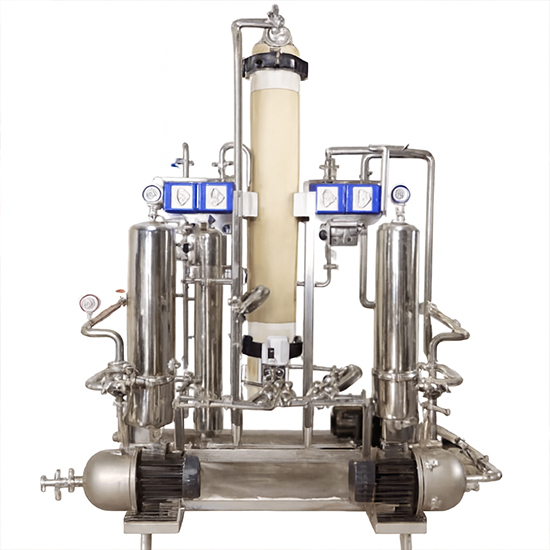

The Feed water is delivered to the ultrafiltration using a pump at a pressure of 2.0 kg/cm2. Ultrafiltration membranes are hollow fiber membranes. Ultrafiltration reduces SDI, organics, microorganisms, and colloidal silica loading.

Feed water is sent to ultrafiltration through a 5-micron pore size cartridge filter to capture suspended solids. This prevents clogging of the ultrafiltration membrane due to suspended solids. High pressure is provided for ultrafiltration to protect the protection system. If the discharge pressure and pressure drop exceed the standard by 15-20%, the system will sound an alarm and if not reached within 5 minutes, the system will automatically shut down.

Ultrafiltration systems are also used in the pharmaceutical industry to obtain high purity water. Ultrafiltration systems with hot water disinfection capabilities can also be used for pharmaceutical applications. Similarly, ultrafiltration units with higher flow rates and ranges are available.

Ultra Filtration (UF) is a membrane-based water purification technology that removes suspended solids, turbidity, colloids, bacteria, and certain viruses from water. It uses a semi-permeable membrane with pore sizes typically in the range of 0.01 to 0.1 microns, ensuring high-quality filtrate without the use of chemicals.

UF is widely used for producing clean, clear, and safe water in industrial, commercial, and municipal applications.

Ultra Filtration System has high filtration precision which uses semi-permeable membranes with pore sizes typically 0.01 - 0.1 microns. They effectively removes suspended solids, colloids, bacteria, viruses, and high-molecular-weight contaminants.

The consistent & reliable water quality delivers uniform permeate quality, independent of feed water variations and ensures stable performance even with fluctuating turbidity. It works efficiently at low pressure (1 - 3 bar) by reducing energy consumption and operational costs.

It undergoes Chemical-Free Filtration, primarily a physical separation process where there is no need for chemicals for basic filtration (chemicals used only for cleaning). The Automatic Backwashing & Chemical Cleaning by Ultra Filtration System is equipped with automatic backwash, forward flush, and chemical-enhanced backwash (CEB) by keeping the membrane clean and prolongs lifespan.

UF modules are compact, easy to install, and suitable for small to large-scale systems. Modular structure allows capacity expansion. UF systems typically achieve 90 - 98% water recovery, reducing waste. Durable membrane materials (PVDF, PES) ensure 5 - 7 years of lifespan with proper maintenance.

Ultra Filtration System removes fine impurities, protecting RO membranes from fouling and scaling and improves RO efficiency and extends membrane life. It requires less space compared to conventional filtration systems and fewer maintenance requirements due to automated cleaning.

It shows robust performance in harsh conditions and effective even in high turbidity or variable raw water sources. It has lower chemical usage and reduced sludge production suitable for sustainable water treatment applications.

Ultra Filtration (UF) is a pressure-driven membrane separation process used to remove suspended solids, bacteria, viruses, colloids, and high-molecular-weight impurities from water. Ultra Filtration works on the principle of size-based separation using semi-permeable membranes under pressure. It removes microscopic impurities while allowing clean water to pass through.

Raw or pre-treated water is fed into the UF system using a pump. The pressure applied normally ranges between 1 to 5 bar. The heart of the system is the UF membrane, which has pore sizes typically around 0.01 - 0.1 microns. When pressure is applied: Clean water (permeate) passes through the membrane. Impurities (retentate) like suspended solids, bacteria, and macromolecules are retained on the membrane surface. This separation occurs based on molecular size and pressure, not on chemical changes.

UF often uses crossflow design: A portion of the water flows tangentially across the membrane. This reduces fouling and allows continuous operation. Contaminants are swept away with the reject stream. The filtered water (permeate) is collected and sent to storage or used for downstream processes such as: RO system feed, Drinking water, Industrial process water. The retained contaminants exit as reject or concentrate stream. This helps maintain membrane performance and reduces clogging.

To maintain efficiency, UF systems undergo periodic cleaning like Backwashing: Reverse flow of clean water through the membrane. Chemical Cleaning (CIP): Removal of stubborn fouling using safe chemicals.

Types of Ultra Filtration (UF) Systems, commonly used in water treatment, industrial processes, and pharmaceutical applications: